Milling sheet material

Machining can handle almost any board material. The technological advancement of the modern machine allows for a very fast and accurate division of the material. Shaped shapes such as radius, grooving, boring and last but not least engraving. Milling of technical plastics.

Dimension of milling area: 2133 x 4267 mm

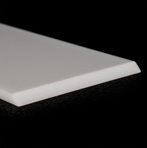

Construction edge

The visible difference between cutting and milling of plastic by sawing.

The visible difference between cutting and milling of plastic by sawing.

Plastic milling is a method of machining sheet material that can be applied to the product without further processing. However it depends on the structure of the plastic material.

Benefits

- construction edge without the need for further work

- high quality and accuracy of product processing

- speeds up the production process

- surface engraving

Materiály

- Acryl PMMA (Plexiglas milling)

- milling of polycarbonate (lexan)

- milling of polyamide

- milling A-PET

- milling of PET-G

- Milling Aluminum Plates (Aluminum)

- Dibond milling

- wood milling (veneer, plywood, MDF)

- milling of technical materials

Angled plastic milling

Here you can see a clean construction edge at an angle of 45°.

Here you can see a clean construction edge at an angle of 45°.

A significant difference and great advantage lies in the technology of machining the plastic with a laser cutter. It brings new possibilities in product design.